Our customers know exactly what is best for their product. And that’s why every one of our special machine construction project is different. As a special machine builder and steel constructor, we offer optimal implementation support from a single source. Whether it is a completely new design or the expansion of existing plants, we look forward to the moment when your plant is put into operation for the first time.

Customer success story: Wax plate plant cools 3.5t of wax per hour

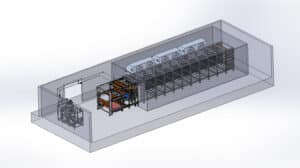

Within the scope of special machine construction, HEIKO Metallbau delivered a fully automatic wax plate plant to a Hungarian customer. The plant, which is capable of cooling up to 3.5t of waxes or paraphines per hour, was developed, designed, delivered and commissioned by HEIKO Metallbau.

Customer success story: Innovative squeeze roller for agriculture

HEIKO Metallbau is pleased to present the successful development of a state-of-the-art squeeze roller for agriculture as its latest project reference. In close co-operation with the experienced design engineer Marcus Schering, this pioneering special machine construction project was developed, which not only impresses local farmers, but has also met with international recognition. The squeegee roller enables efficient work in the field, inhibits weed growth and offers a sustainable solution for agricultural soil cultivation. HEIKO Metallbau proudly demonstrates its expertise in the field of special machine construction with this innovative and successful project.